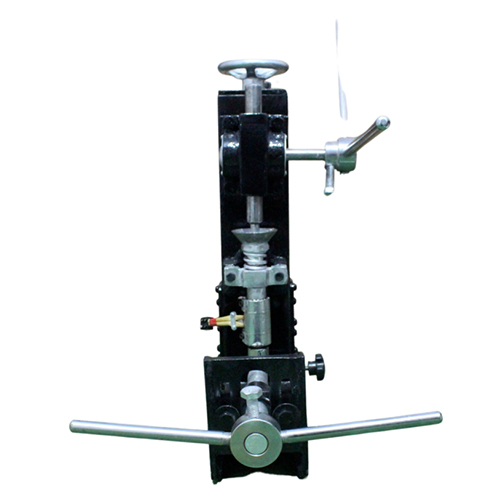

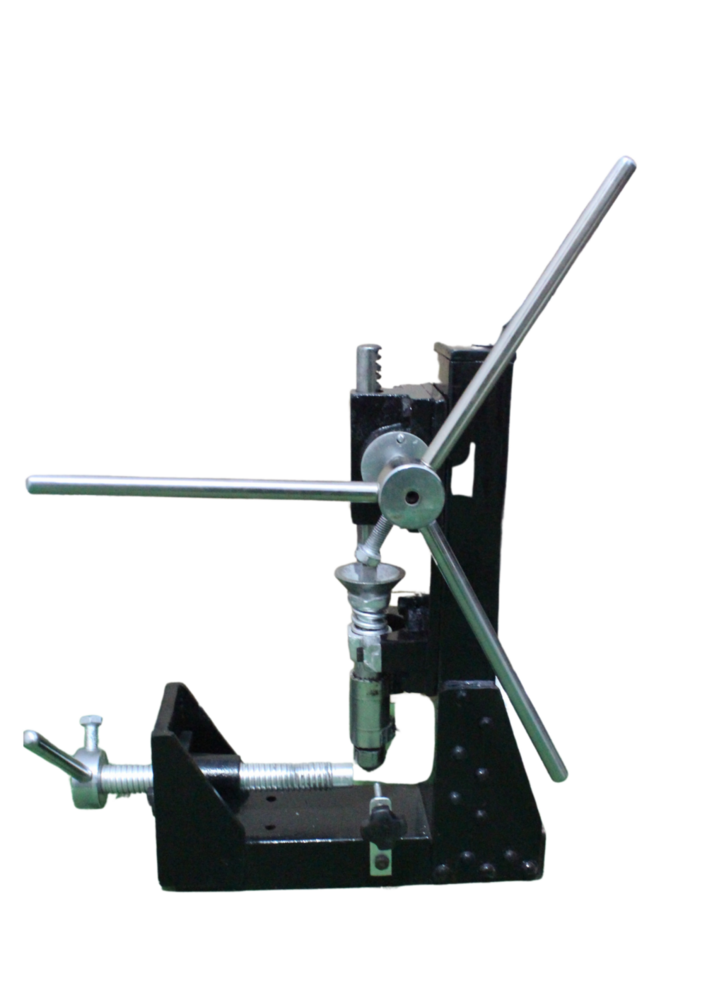

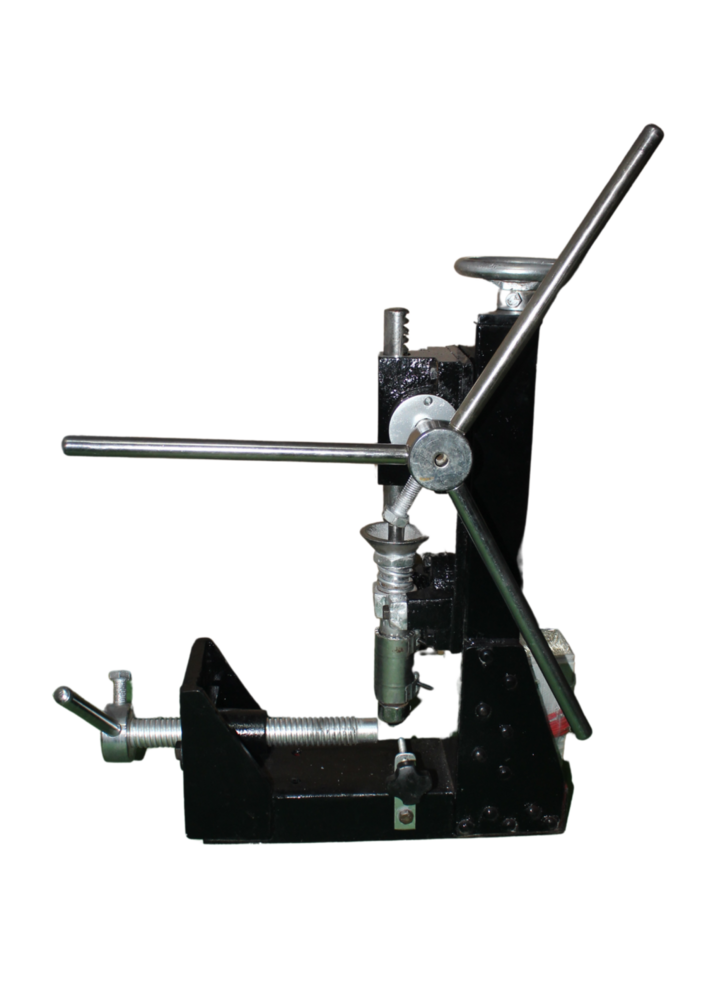

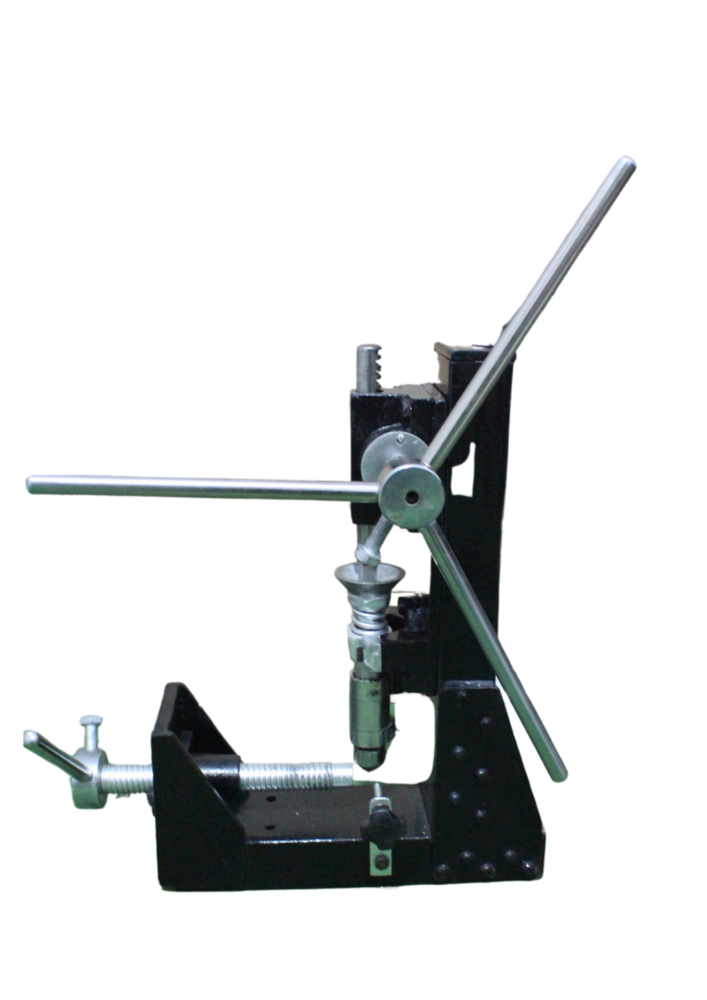

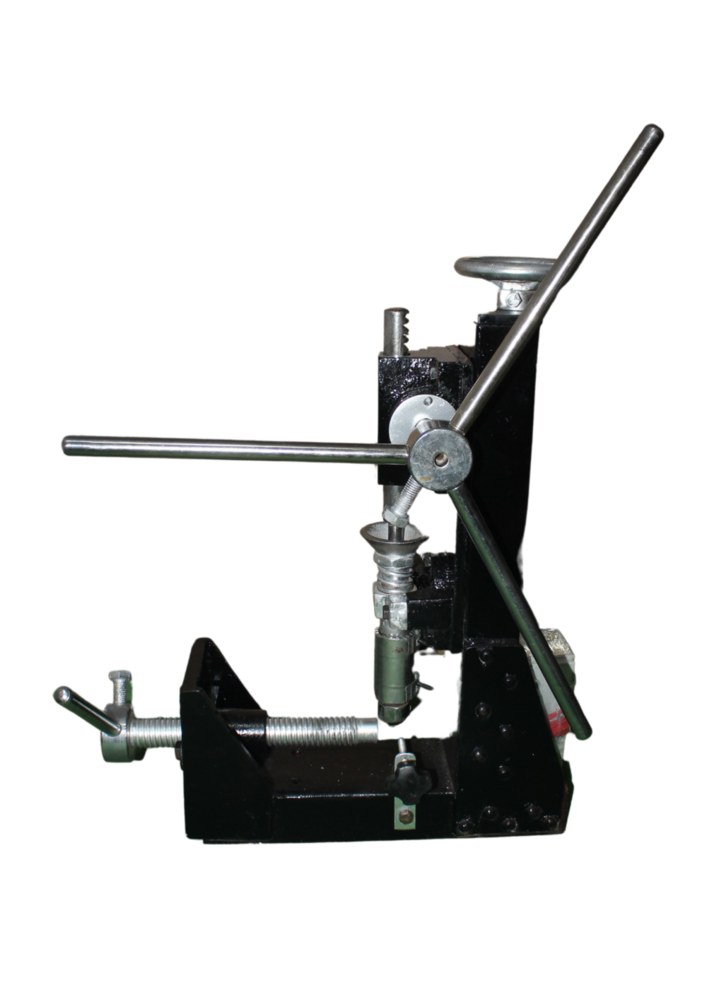

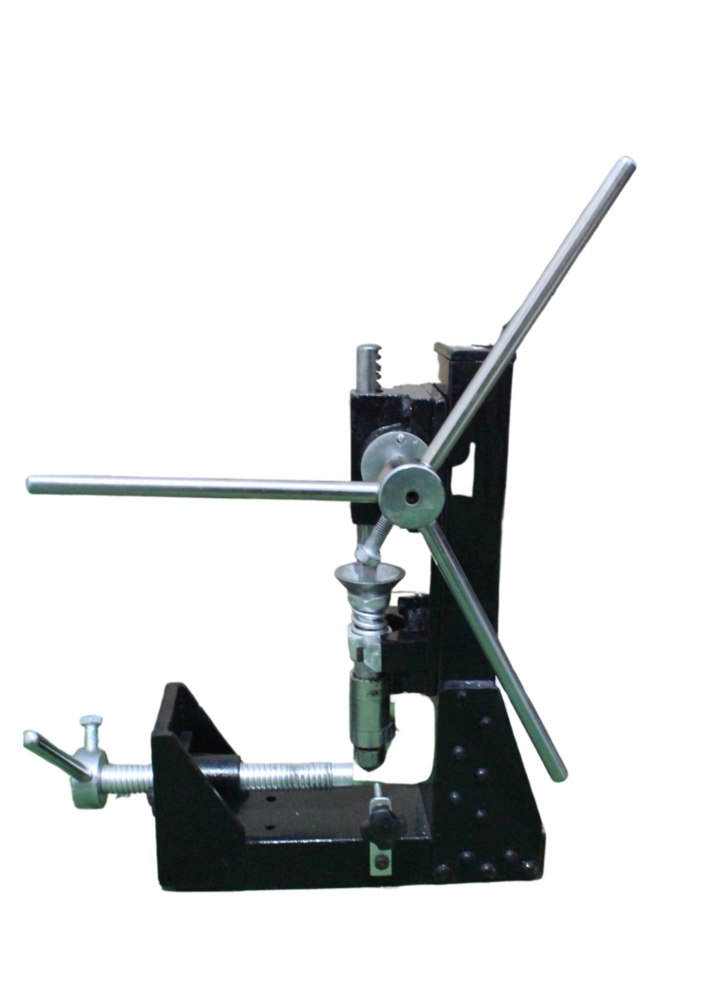

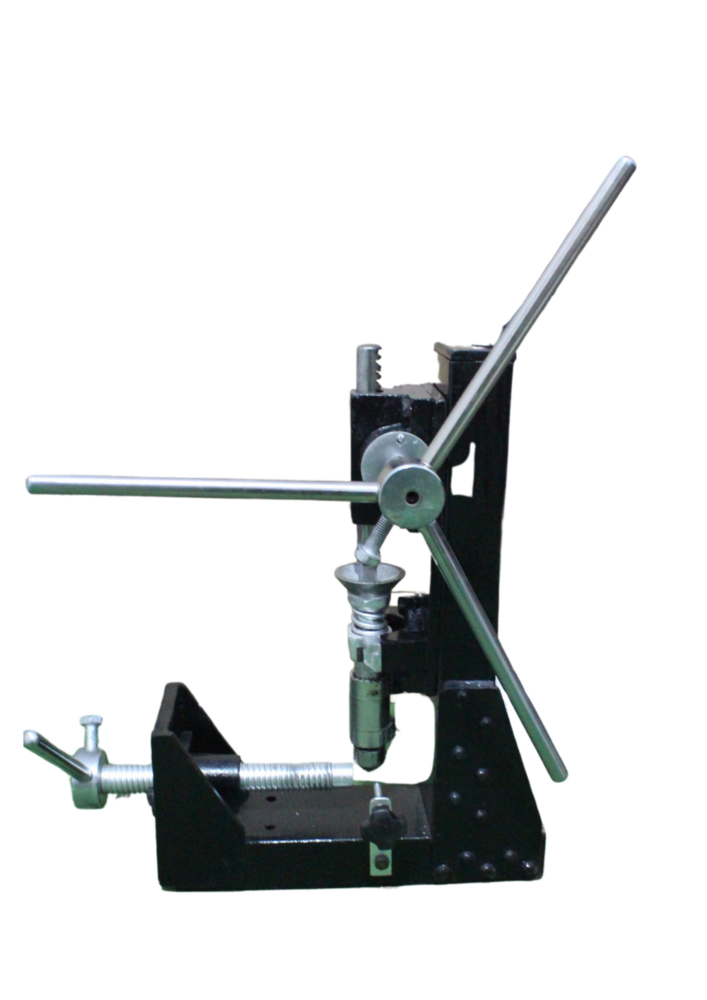

HAND MOLDING MACHINE

Price 11990 INR/ Piece

HAND MOLDING MACHINE Specification

- Noise Level

- Low (Manual Operation)

- Drive

- Manual

- Lubricating System

- Periodic Manual Lubrication

- Machine Type

- Hand Operated Molding

- Accuracy

- Standard (Based on Operator Skill)

- Model No

- Standard/Specified by Manufacturer

- Power Rating

- N/A (Manual)

- Operating Temperature

- Ambient

- Frame Type

- Solid Cast Iron Frame

- Features

- Durable Construction, Portable, Easy Operation

- Product Type

- Hand Molding Machine

- Technology

- Traditional Sand Molding

- Power Source

- Manual

- Operating Type

- Hand Operated

- Pressure

- Manual (Hand Operated)

- Surface Treatment

- Painted/Cast Iron Finish

- Dimension (L*W*H)

- Approx. 700mm x 500mm x 400mm

- Weight (kg)

- 50-80 Kg (Depending on Model)

- Color

- Green/Custom

- Production Capacity

- 40-50 Molds per Shift

- Usage & Applications

- Foundry Sand Casting, Molding Workshops, Small Scale Foundries

About HAND MOLDING MACHINE

-

Injection Molding Machine: This is the most common type used in the plastics industry. It injects molten plastic into a mold cavity under high pressure. The plastic is then cooled to form a solid part. It is used to produce small, precise, and complex shapes.

-

Blow Molding Machine: Used to create hollow plastic parts, such as bottles and containers. The machine inflates a softened tube of plastic inside a mold to form the desired shape.

-

Compression Molding Machine: Used for molding rubber and thermosetting plastics. The material is placed in a mold cavity and compressed by a heated press. The material is then allowed to cure, taking the shape of the mold.

-

Rotational Molding Machine: This process is used to make large hollow parts, such as tanks and containers. The mold is heated and rotated along two perpendicular axes while the material (usually plastic powder) melts and coats the inside of the mold.

-

Thermoforming Machine: In this process, a sheet of plastic is heated until it is soft and then stretched over a mold to form a specific shape.

Key Components of a Molding Machine:

- Injection Unit: This is responsible for melting and injecting the material into the mold.

- Clamping Unit: Holds the mold in place during the injection process, and provides the force required to open and close the mold.

- Mold: The custom-designed cavity that defines the shape of the finished product.

- Hydraulic System: Powers the injection and clamping units, providing the force needed for the molding process.

- Control System: A computer or manual interface used to adjust the machine's settings, monitor performance, and ensure quality control.

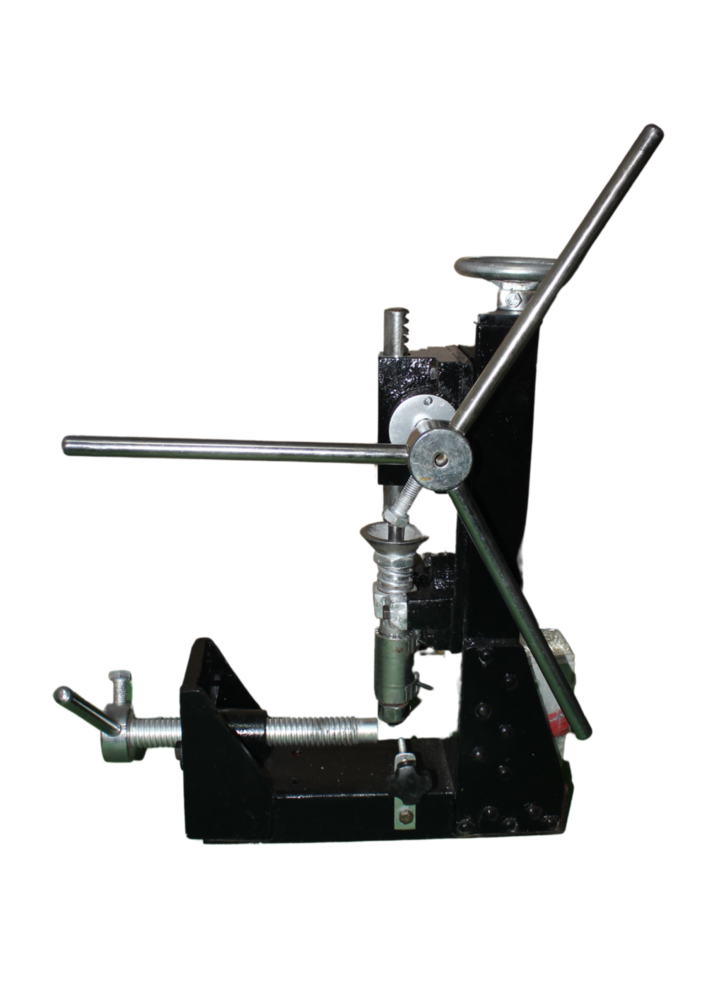

Efficient and Versatile Sand Molding Solution

Engineered for foundries and molding workshops, this hand-operated molding machine excels in both ferrous and non-ferrous applications. With a solid cast iron frame and user-friendly controls, it ensures consistent results and long-lasting performance. Its portability, low maintenance, and eco-friendly operation make it a practical choice for businesses prioritizing sustainability and versatility in sand casting.

A Reliable Addition for Every Molder

Designed for optimal ease of use, the machine features mechanical safety stops, minimal noise output, and simple manual controls. Whether you're a beginner seeking an accessible introduction to sand molding or a professional pursuing reliability and capacity, this machine offers straightforward, accurate operation and adaptability to suit diverse casting requirements.

FAQ's of HAND MOLDING MACHINE:

Q: How does the hand molding machine with a quick action mechanical clamp operate?

A: This machine operates entirely by manual force, utilizing a quick action mechanical clamp to secure the flask. Its design allows a single operator to manually assemble molds, ram sand, and securely clamp the flask, streamlining the traditional sand molding process without electrical power.Q: What types of castings can be produced using this hand molding machine?

A: The machine is compatible with both ferrous and non-ferrous castings, making it suitable for a wide variety of sand casting applications found in small-scale foundries and molding workshops.Q: When should I consider using the optional core making facility?

A: The optional core making attachment is ideal when your casting process requires intricate internal geometries or hollow sections within your finished part. You can choose to add this feature when your production needs evolve to include such complexities.Q: Where can this machine be installed and used effectively?

A: Thanks to its compact size, portability (with rubber pads/feet), and lack of electrical requirements, the machine can be installed in almost any foundry, molding workshop, or small industrial space that requires ambient temperature operation and manual casting production.Q: What is the molding process like with this machine, and is it user-friendly?

A: The process involves preparing the molding flask, ramming sand around the pattern, and using the quick action clamp for secure closure-all performed manually. Designed for ease of use, even beginners can learn the operation quickly, while professionals can enjoy rapid, reliable molding.Q: What are the benefits of choosing this hand molding machine for my foundry?

A: Key benefits include eco-friendly operation with no electric power consumption, a low maintenance requirement, robust cast iron construction for extended service life, and the flexibility to accommodate various flask sizes and custom requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Molding Machine Category

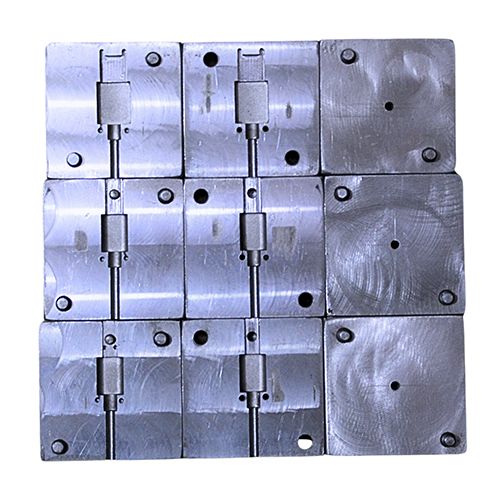

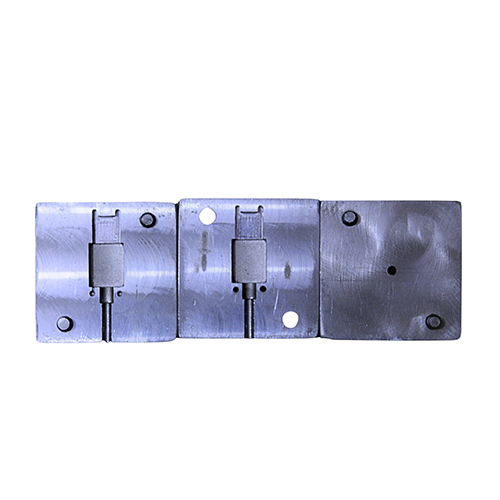

DATA CABLE MOLD DIE

Price 4999.0 INR

Minimum Order Quantity : 1

Usage & Applications : Data cable and connector manufacturing

Power Source : Other, Electric

Surface Treatment : Other, Polished / Heat Treated

Color : Grey / Metallic

DATA CABLE DIE MOLD

Price 4999.0 INR

Minimum Order Quantity : 1 Piece

Usage & Applications : For forming data cable connectors and components, suitable for mobile, USB, and electronic connector manufacturing

Power Source : Other, Electric

Surface Treatment : Other, Polished & Nitrided

Color : Metallic Silver/Grey

DATA CABLE DIE

Price 4899.0 INR

Minimum Order Quantity : 1

Usage & Applications : Wire and cable manufacturing; Data cable forming and cutting

Power Source : Other, Electric

Surface Treatment : Other, Polished/Fine Finish

Color : Silver/Grey

SEMI AUTO MOLDING MACHINE 40GRAM

Price 124999.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Power Source : Electricity

Surface Treatment : Painted

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry