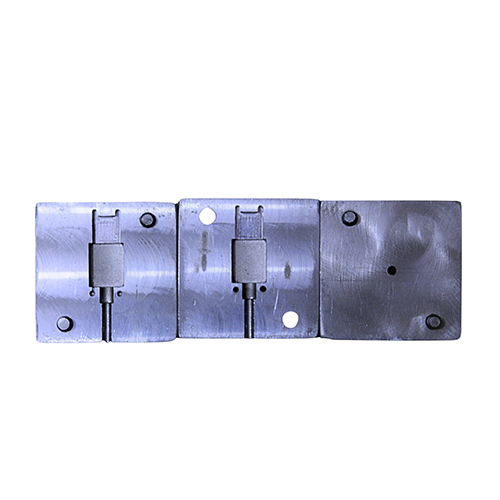

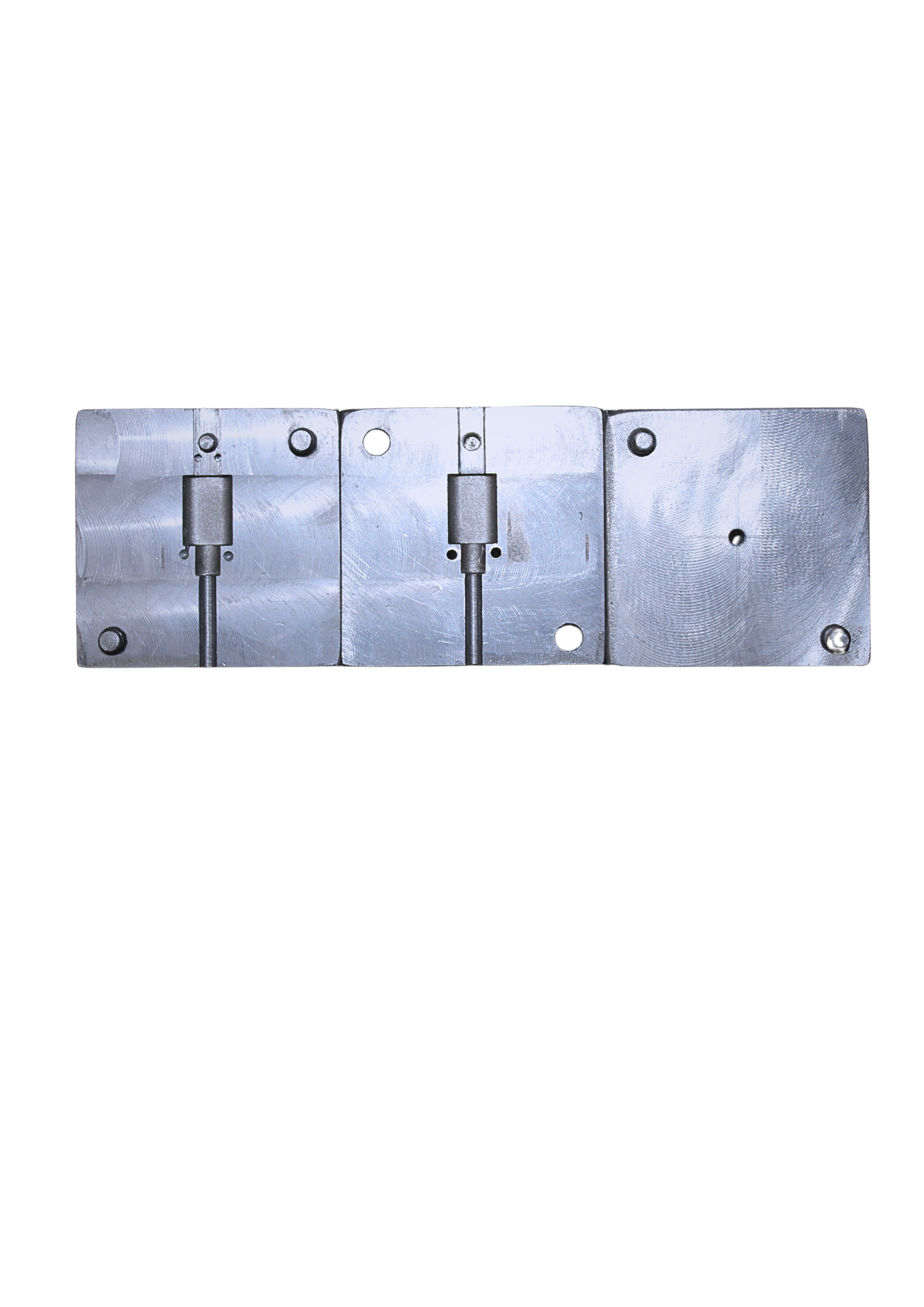

DATA CABLE MOLD DIE

DATA CABLE MOLD DIE Specification

- Connectivity Options

- For USB, Micro USB, Type C and more

- Frame Type

- Standard

- Operating Temperature

- Up to 200C

- Power Rating

- Standard

- Plastic Processed

- PVC, ABS, PP

- Features

- Corrosion Resistance, Dimensional Accuracy, Durable

- Frequency

- 50/60 Hz

- Cooling System

- Water / Air cooled

- Voltage

- 220-380 V

- Motor Power

- 2 HP

- Drive

- Servo / Hydraulic

- Production Capacity

- 1000-5000 pcs per month

- Lubricating System

- Automatic / Manual

- Noise Level

- Low

- Control System

- Manual/PLC (Optional)

- Accuracy

- High Precision +/- 0.01 mm

- Machine Type

- Plastic Molding Die

- Model No

- DCMD-23

- Product Type

- Data Cable Mold Die

- Technology

- Injection Molding

- Power Source

- Electric

- Operating Type

- Manual / Semi-Automatic

- Power

- 2-5 kW

- Pressure

- High Precision Molding Pressure

- Surface Treatment

- Polished / Heat Treated

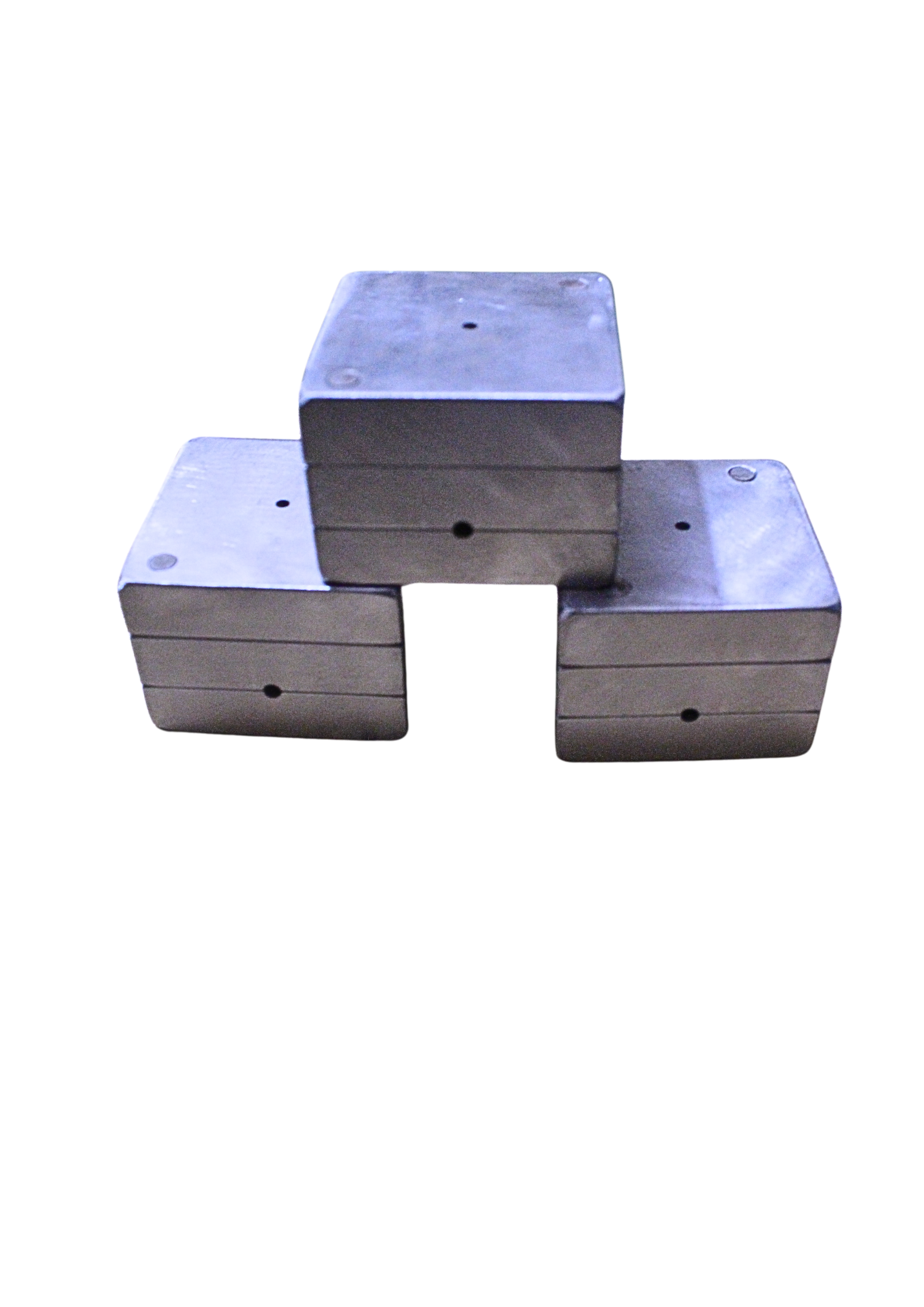

- Dimension (L*W*H)

- Customized as per requirement

- Weight (kg)

- 15 - 40 kg

- Color

- Grey / Metallic

- Usage & Applications

- Data cable and connector manufacturing

DATA CABLE MOLD DIE Trade Information

- FOB Port

- 1

- Supply Ability

- 1 Per Day

- Delivery Time

- 3 Days

- Packaging Details

- APS STAR DELHI

- Main Domestic Market

- [, ]

About DATA CABLE MOLD DIE

Purpose of Data Cable Die

- The die is a tool used during the extrusion process to shape the data cable. Extrusion involves forcing raw materials (such as copper wires, plastic insulation, and other components) through the die to create the final shape of the wire.

- The die determines the size, shape, and structure of the cable, ensuring that the insulation, conductors, and protective outer layers are uniform and meet design specifications.

2. Components of a Data Cable Die

- Extruder Die: This part of the die has a specifically designed opening through which the raw material is forced. It shapes the cable's core, insulation, or outer covering as the material is extruded.

- Material Feed: The die receives materials such as copper for conductors, insulation materials (PVC, Teflon, PE), and sometimes fillers or shields for added durability.

- Cooling System: After the extrusion, the material needs to cool down and solidify. The die may have built-in cooling channels or water sprays to ensure the correct temperature for the extrusion process.

3. Types of Dies Used in Cable Manufacturing

- Wire Drawing Die: Used to pull the copper wire to the desired thickness before it's coated with insulation.

- Extrusion Die: A die used for extruding insulation material around the wire. This is crucial for creating the proper coating around each individual conductor inside the data cable.

- Shielding Die: Some data cables (like coaxial cables) require additional shielding. This type of die helps to apply a metal shield (often copper or aluminum) around the wire to reduce electromagnetic interference (EMI).

- Jacketing Die: This die is used to apply the outer layer or jacket of the cable, ensuring it is durable, flexible, and resistant to environmental factors.

4. Die Materials

- Steel: The most common material for data cable dies is hardened steel because of its durability and resistance to wear.

- Tungsten Carbide: Used in high-precision or high-wear applications, such as for drawing fine wires.

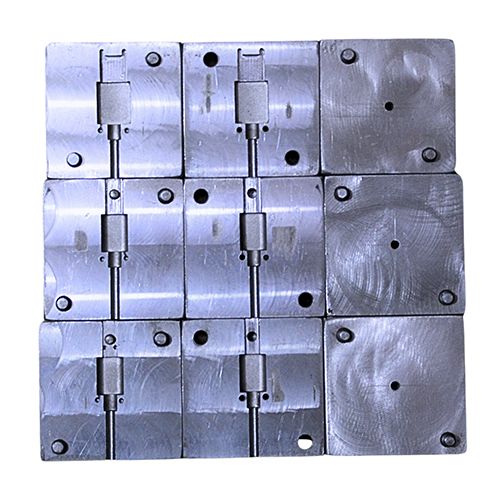

Advanced Cavity Customization

Benefit from single or multi-cavity designs tailored to your specific manufacturing volumes and connector types. The die's flexibility enables efficient production runs, ensuring consistent quality whether you need limited or large-scale output.

Unmatched Mold Longevity

Constructed with premium tool steel and high standards of surface treatment, this die achieves a lifespan of up to 800,000 shots. Carefully selected materials and heat treatment provide exceptional corrosion resistance, keeping maintenance minimal and performance optimal.

Precision and Versatility

The DATA CABLE MOLD DIE delivers unmatched precision with a dimensional accuracy of 0.01 mm. Its adaptable features, from runner systems to cooling options, support a broad spectrum of plastic materials and connector applications, ensuring reliable results every time.

FAQ's of DATA CABLE MOLD DIE:

Q: How is the DATA CABLE MOLD DIE customized to specific production needs?

A: Customization is available across multiple parameters, including cavity count (single or multi-cavity), mold dimensions, cooling and runner systems, and finish quality. We tailor each die as per your connector types, production targets, and technical requirements.Q: What is the process for manufacturing with this mold die?

A: The process involves precision injection molding of plastics like PVC, ABS, or PP under high pressure using either manual or semi-automatic operation. The interchangeable assembly design allows for quick adjustments, while automatic or manual lubrication ensures smooth production.Q: When should I select a hot runner versus a cold runner system?

A: Choose a hot runner system for high-volume, continuous production as it reduces material waste and enhances cycle speed. Opt for a cold runner system for smaller batches or where material compatibility and simplicity are priorities.Q: Where can the mold die be used and for what types of connectors?

A: The DATA CABLE MOLD DIE is suitable for plastic molding facilities and cable manufacturing units, supporting the production of USB, Micro USB, Type C, and other data cable connectors.Q: What are the main benefits of using this high-grade mold die?

A: Major benefits include superior dimensional accuracy, a mirror polished or EDM finish for burr-free edges, high corrosion resistance, and a long operational life. These features help ensure minimal maintenance and high production consistency.Q: How do I maintain the mold die for longevity and performance?

A: Regular cleaning, timely lubrication (automatic or manual), and periodic inspection of assembly parts are recommended. The corrosion-resistant materials and heat-treated surfaces further reduce the frequency of maintenance required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Molding Machine Category

DATA CABLE DIE MOLD

Price 4999.0 INR

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Usage & Applications : For forming data cable connectors and components, suitable for mobile, USB, and electronic connector manufacturing

Surface Treatment : Other, Polished & Nitrided

Product Type : Other, Data Cable Die Mold

DATA CABLE DIE

Price 4899.0 INR

Minimum Order Quantity : 1

Power Source : Other, Electric

Usage & Applications : Wire and cable manufacturing; Data cable forming and cutting

Surface Treatment : Other, Polished/Fine Finish

Product Type : Other, Data Cable Die

15 TON MOLDING MACHINE

Price 189999.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electricity

Usage & Applications : Industrial

Surface Treatment : Painted

SEMI AUTO MOLDING MACHINE 40GRAM

Price 124999.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electricity

Usage & Applications : Industrial

Surface Treatment : Painted

Product Type : Milling Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry