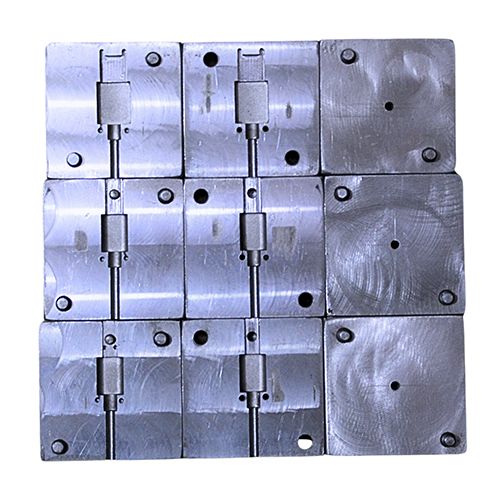

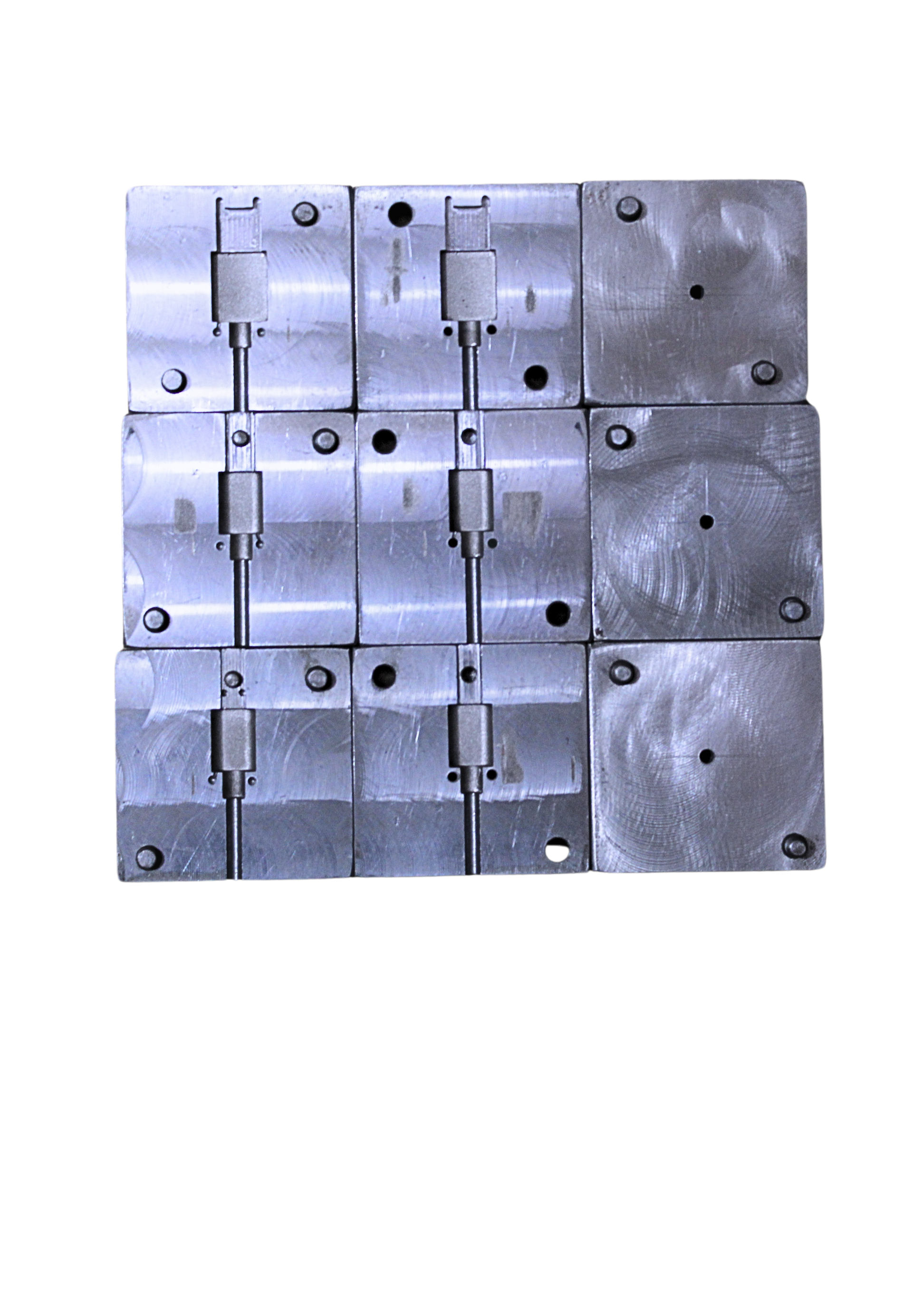

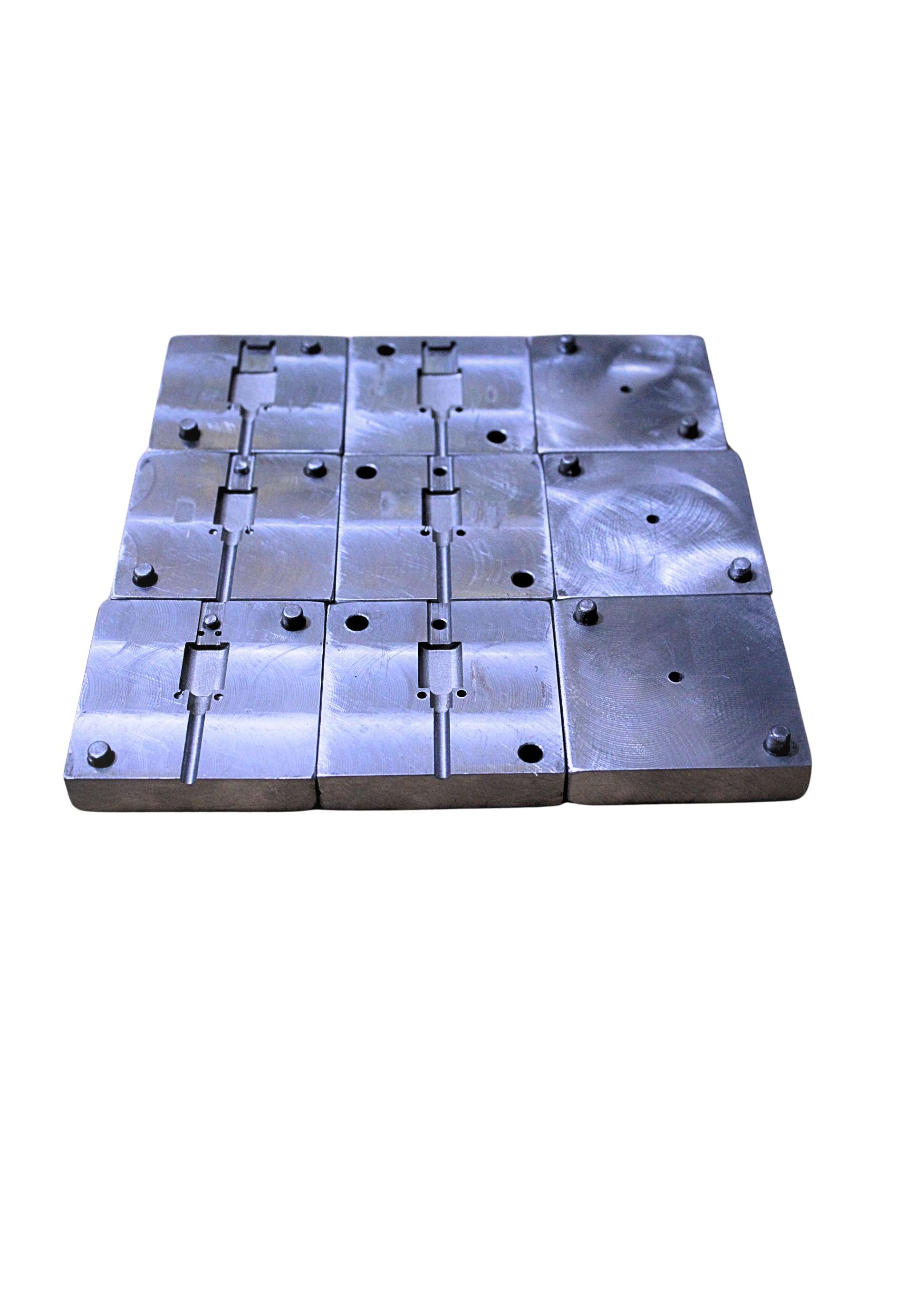

DATA CABLE DIE

DATA CABLE DIE Specification

- Motor Power

- 1.5 kW

- Cooling System

- Water/Oil Cooling Optional

- Noise Level

- Low (<70 dB)

- Lubricating System

- Automatic Lubrication

- Voltage

- 220-240V

- Operating Temperature

- 10C - 45C

- Frequency

- 50/60 Hz

- Accuracy

- 0.01 mm

- Drive

- Electric Drive

- Production Capacity

- 5000 units/month

- Frame Type

- Sturdy/Heavy Duty

- Plastic Processed

- PVC, ABS, TPE

- Connectivity Options

- Mechanical Interface

- Power Rating

- 1.2 kW

- Control System

- Manual/Semi-Automatic

- Machine Type

- Custom Die for Data Cable

- Features

- Corrosion Resistant, High Durability, Easy to Install

- Model No

- DCD-1027

- Product Type

- Data Cable Die

- Technology

- CNC Machining

- Power Source

- Electric

- Operating Type

- Manual/Semi-Automatic

- Power

- 1-2 kW

- Pressure

- High Precision/Customizable

- Surface Treatment

- Polished/Fine Finish

- Dimension (L*W*H)

- Custom/Standard Sizes Available

- Weight (kg)

- 5-20 Kg (depending on model)

- Color

- Silver/Grey

- Usage & Applications

- Wire and cable manufacturing; Data cable forming and cutting

DATA CABLE DIE Trade Information

- Delivery Time

- 3 Days

- Packaging Details

- APS STAR DELH I

- Main Domestic Market

- [, ]

About DATA CABLE DIE

Purpose of Data Cable Die

- The die is a tool used during the extrusion process to shape the data cable. Extrusion involves forcing raw materials (such as copper wires, plastic insulation, and other components) through the die to create the final shape of the wire.

- The die determines the size, shape, and structure of the cable, ensuring that the insulation, conductors, and protective outer layers are uniform and meet design specifications.

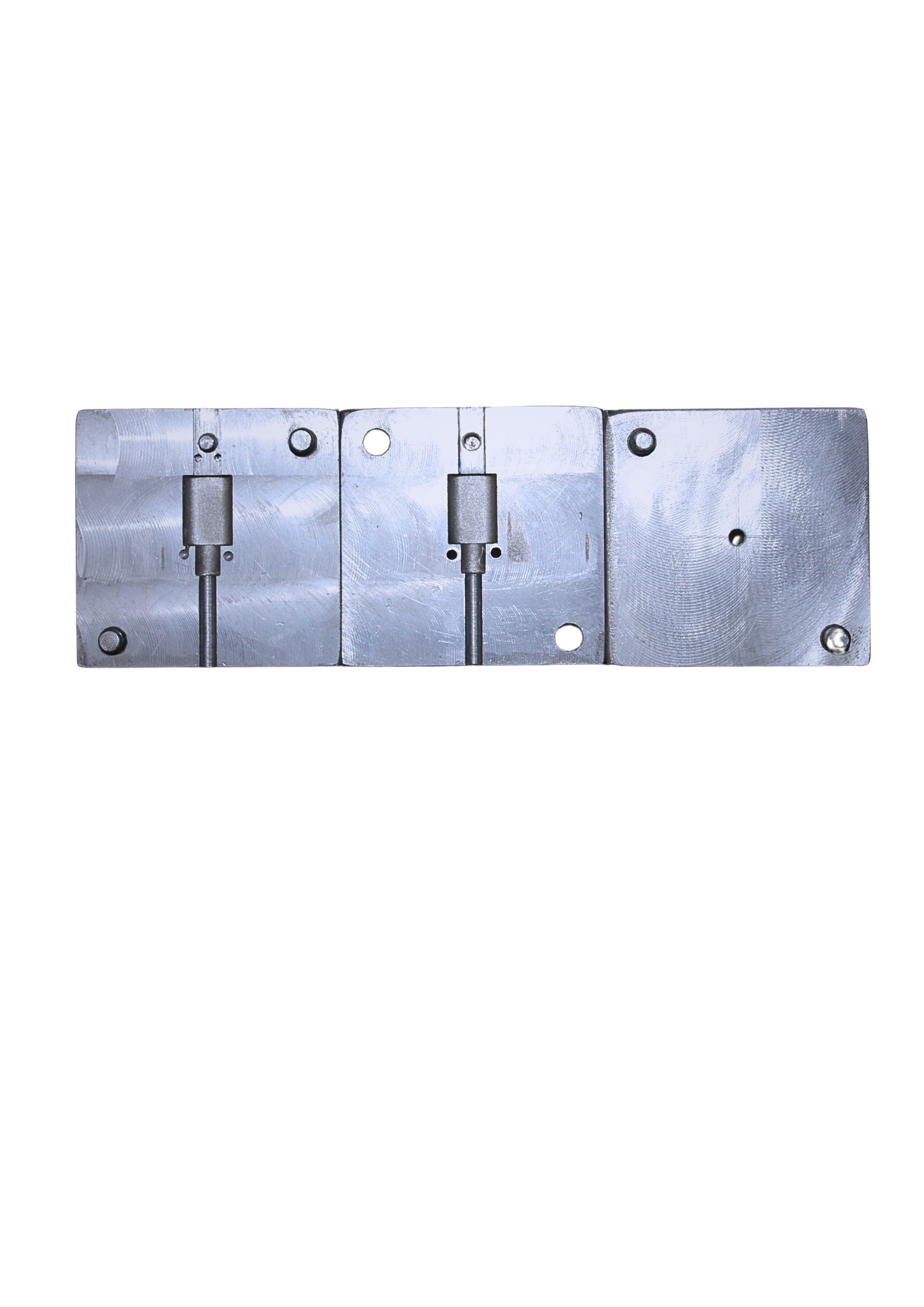

2. Components of a Data Cable Die

- Extruder Die: This part of the die has a specifically designed opening through which the raw material is forced. It shapes the cable's core, insulation, or outer covering as the material is extruded.

- Material Feed: The die receives materials such as copper for conductors, insulation materials (PVC, Teflon, PE), and sometimes fillers or shields for added durability.

- Cooling System: After the extrusion, the material needs to cool down and solidify. The die may have built-in cooling channels or water sprays to ensure the correct temperature for the extrusion process.

3. Types of Dies Used in Cable Manufacturing

- Wire Drawing Die: Used to pull the copper wire to the desired thickness before it's coated with insulation.

- Extrusion Die: A die used for extruding insulation material around the wire. This is crucial for creating the proper coating around each individual conductor inside the data cable.

- Shielding Die: Some data cables (like coaxial cables) require additional shielding. This type of die helps to apply a metal shield (often copper or aluminum) around the wire to reduce electromagnetic interference (EMI).

- Jacketing Die: This die is used to apply the outer layer or jacket of the cable, ensuring it is durable, flexible, and resistant to environmental factors.

4. Die Materials

- Steel: The most common material for data cable dies is hardened steel because of its durability and resistance to wear.

- Tungsten Carbide: Used in high-precision or high-wear applications, such as for drawing fine wires.

Engineered for Precision and Durability

Designed with advanced CNC machining, the DATA CABLE DIE offers exceptional precision, achieving a 0.01 mm accuracy ideal for quality cable manufacturing. Its construction from tool and alloy steel ensures long mould life and consistent performance, making it suitable for rigorous production cycles in demanding industries.

Customizable to Your Specifications

Choose from single or multiple cavity configurations and tailor the dimensions, size, or design as per your project requirements. With finish options-including mirror and matte-plus optional water or oil cooling and secure packaging, this die adapts seamlessly to varied manufacturing needs.

Efficient, Safe, and Simple to Operate

The die supports both manual and semi-automatic operation types with an intuitive control system, high-speed performance, and low noise levels (<70 dB). Its automatic lubrication and corrosion-resistant frame make installation and ongoing maintenance straightforward, maximizing uptime and operator safety.

FAQ's of DATA CABLE DIE:

Q: How is the DATA CABLE DIE installed and maintained?

A: The DATA CABLE DIE is designed for easy installation due to its sturdy frame and compact size range (5-20 kg). Maintenance is minimal, thanks to its automatic lubrication system and corrosion-resistant construction, ensuring long-lasting use with infrequent service needs.Q: What materials can be processed with this die?

A: The die is capable of processing a range of plastics, including PVC, ABS, and TPE, which are commonly used in data cable manufacturing. This versatility makes it ideal for producing different types of data cable sheaths and components.Q: When should mirror or matte finish options be selected?

A: Mirror finishes are recommended when a smooth, glossy cable surface is desired, while matte finishes are suitable for non-reflective, textured requirements. The choice depends on end application aesthetics and functional specifications.Q: Where can this die be used in terms of industries and applications?

A: The DATA CABLE DIE is widely used in telecommunications, electronics, and automotive sectors for forming and cutting USB, micro USB, and Type-C data cables, ensuring compatibility with diverse cable types and manufacturing lines.Q: What is the benefit of having high-speed operation and high-precision capability?

A: High-speed operation ensures increased manufacturing throughput (up to 5,000 units/month), while precision down to 0.01 mm delivers consistent and reliable product quality, reducing material waste and improving productivity.Q: How does the cooling and lubrication system work?

A: Optional water or oil cooling maintains optimal operating temperatures, and the automatic lubrication system reduces friction, prolonging the die's life and ensuring smoother operation during high-volume production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Molding Machine Category

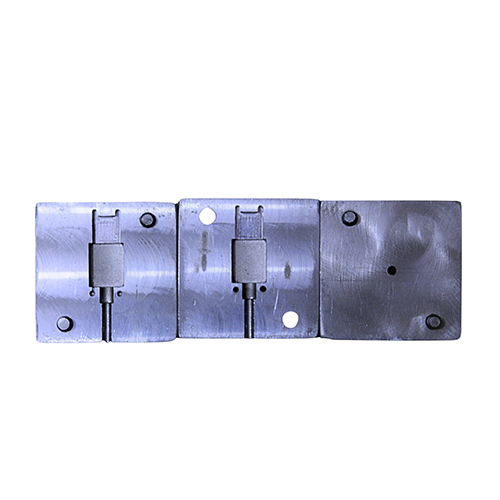

DATA CABLE MOLD DIE

Price 4999.0 INR

Minimum Order Quantity : 1

Power Source : Other, Electric

Usage & Applications : Data cable and connector manufacturing

Color : Grey / Metallic

Product Type : Other, Data Cable Mold Die

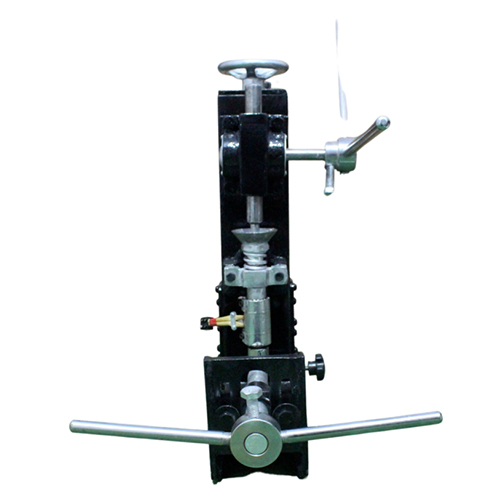

HAND MOLDING MACHINE

Price 11990 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Other, Manual

Usage & Applications : Foundry Sand Casting, Molding Workshops, Small Scale Foundries

Color : Green/Custom

Product Type : Other, Hand Molding Machine

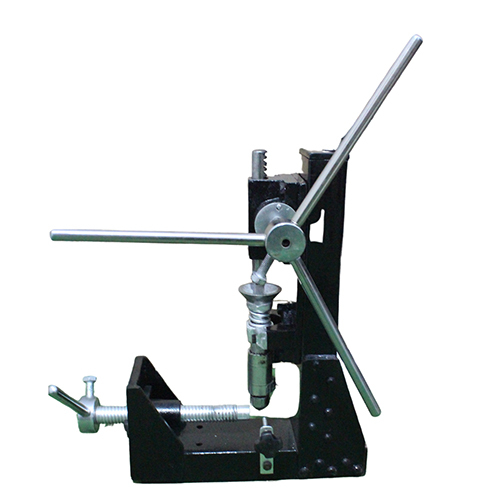

HAND MOLDING MACHINE 20gm

Price 11999.0 INR / Piece

Minimum Order Quantity : 1

Power Source : Electricity

Color : NA

Product Type : Filling Machine

SEMI AUTO MOLDING MACHINE 40GRAM

Price 124999.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electricity

Usage & Applications : Industrial

Product Type : Milling Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry